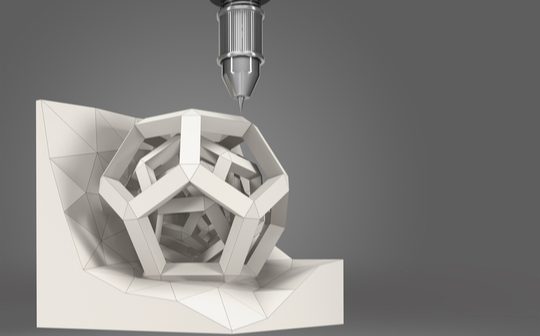

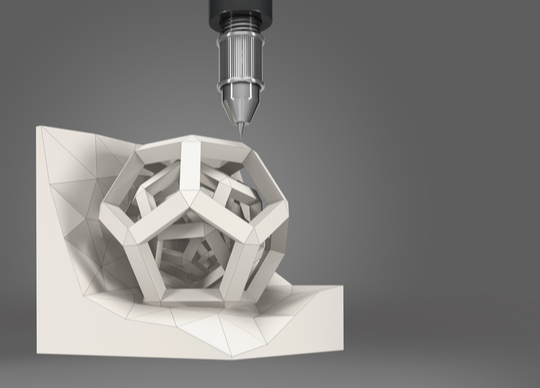

Fleet Space has partnered with Konica Minolta to implement 3D printers from 3D Systems. The 3D printer will also scale up Fleet Space’s manufacturing of small satellites for low Earth orbit to connect billions of devices.

The small satellites from Fleet Space incorporate the world’s first 3D-printed, all-metal patch antenna, which delivers 10 times more throughput per kilogram of spacecraft. The 3D printing of these antennae was outsourced to an offshore provider; however, significant scale-up efficiencies can be found in bringing production to Australia. Fleet Space has been contracted to scale its operations significantly in 2022 and 2023 and needed a more efficient way to 3D print these antennae at scale.

Matthew Hunter, national manager, emerging technology, Konica Minolta, said, “Fleet Space is one of Australia’s most innovative companies, pushing the boundaries of what’s possible. However, this level of innovation often comes at a significant cost. Fleet Space is harnessing the efficiencies that can be found by deploying a smart, in-house 3D printing solution.

“Konica Minolta reached out to Fleet Space to start a discussion and begin a proof of concept to prove that the 3D Systems DMP350 Flex metal 3D printing solution could deliver the outcomes Fleet Space required.”

Konica Minolta and 3D Systems then worked with Fleet Space to develop a build strategy, first proving that the DMP350 was capable of printing the quality of aluminium part and in the volume required for Fleet Space to keep up with demand. This process was key in Fleet Space’s decision to implement the DMP350 metal printer.

Flavia Tata Nardini, CEO and co-founder, Fleet Space, said, “Fleet Space has a mission to unlock the power of global connectivity to effect true change for our critical industries. For example, we are making critical energy transition mineral exploration faster, more sustainable, and less expensive. This is not possible without the very best technical partners. We are delighted to work with Konica Minolta to deliver an entirely new constellation of fully 3D-printed satellites at scale and to the very highest technical specifications.”

Matthew Hunter said, “This is a highly technical environment with precise specifications. Konica Minolta was able to prove that the 3D Systems metal printers include market-leading technology that lets users 3D print with aluminium in a precise, repeated, and scalable method. This made Fleet Space both more productive and cost effective for its volume manufacturing offices and provides ongoing capacity for important research and development, keeping the organisation at the cutting edge.”

Fleet Space initially plans to use the 3D printer to scale up manufacturing of the metal antennae. However, the efficiencies provided by this new device will let Fleet Space ramp up innovation at the same time, using it to develop prototypes and new parts during downtime from manufacturing the antennae.

Matthew Hunter said, “The consultative approach taken by Konica Minolta and 3D Systems means that Fleet Space will be able to go straight into volume manufacturing as soon as the device arrives.”

Tim Naylor, SEANZ Industrial Solutions group leader, 3D Systems, said, “One of the key criteria for Fleet Space was that the 3D printer could deliver a repeatable process to avoid any variation between parts. Our printer has a closed-loop architecture, which guarantees an accurate and repeatable process. The machine also has the lowest oxygen content on the market, which delivers a pure part without defects, something that is very important when it comes to aerospace applications.”

Matthew Hunter said, “Konica Minolta identified Fleet Space’s business issue and recommended the right technology to overcome that issue. The team also determined the financial viability of the project and brought in application experts from Fleet Space and 3D Systems to work through the manufacturing process to achieve the right physical part outcome. The team at Fleet Space is extremely excited about this 3D printer as it will be both a manufacturing tool and an innovation enabler.”