An Australian-led additive manufacturing research project is aiming to address one of the most persistent challenges in space, defence and subsea operations: the delivery of reliable, long-duration power in environments where maintenance, refuelling or solar energy are impractical.

The project, backed by the Additive Manufacturing Cooperative Research Centre (AMCRC), is supporting South Australian nuclear engineering and technology company entX to transition its GenX betavoltaic power generator from prototype to pre-commercial manufacture. It marks the first funded research project under the AMCRC programme.

Developed in collaboration with the University of Adelaide, the GenX system is a next-generation nuclear battery that combines additive manufacturing with advanced surface engineering to deliver high power density in an ultra-compact form factor. The technology is intended for use in applications such as spacecraft, unmanned underwater vehicles and remote defence surveillance systems, where conventional power sources face significant limitations.

“Reliable, long-life power is one of the biggest bottlenecks facing space, subsea and defence systems,” said Dr Scott Edwards, General Manager for Space and Defence at entX. “GenX fundamentally changes what’s possible by re-engineering betavoltaics as ultra-thin, additively manufactured devices that enable power densities previously out of reach.”

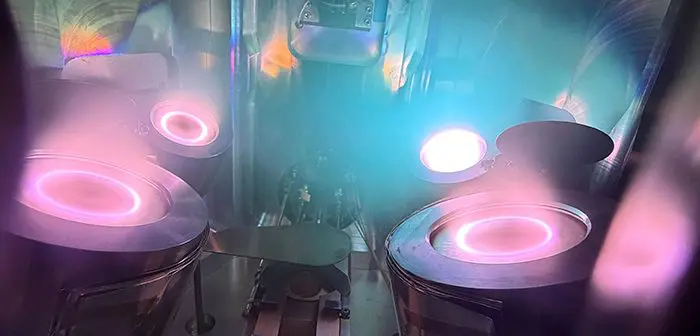

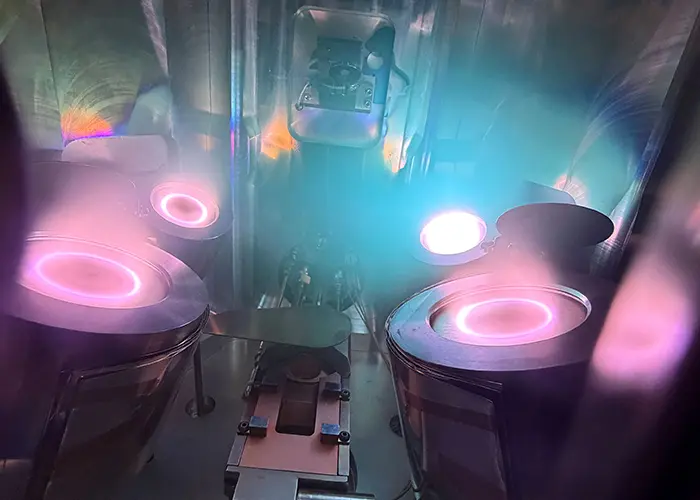

At the core of the GenX technology is a manufacturing process that integrates additive manufacturing with coating and thin-film deposition techniques. Nanoscale layers of metals, metal oxides and semiconductors are deposited sequentially to form complex functional architectures, producing ultra-thin betavoltaic films that exceed current global performance benchmarks.

Professor Drew Evans, who helped develop the GenX prototype and will lead the research at the University of Adelaide, said the approach represents a step-change rather than an incremental improvement.

“By combining novel semiconductor deposition methods with additive manufacturing and surface engineering, we’ve demonstrated betavoltaic devices with power densities that were not achievable using conventional manufacturing approaches,” he said.

Over the next 14 months, the project will focus on validating both the GenX device and its manufacturing process in preparation for customer evaluation. Key activities include transitioning critical prototype processes, such as physical vapour deposition used to form high-efficiency electrical junctions, into a scalable additive manufacturing workflow at entX’s certified radiation facility in Adelaide.

Additive manufacturing will also be used to rapidly prototype radiation-shielded encasements to support safe integration of the technology into space, defence and remote systems.

“This A$1.8 million project demonstrates how additive manufacturing can take breakthrough research and make it manufacturable at scale,” said Simon Marriott, Managing Director of the Additive Manufacturing CRC. “By supporting the transition from laboratory prototype to integrated production, we are helping Australian innovators reduce risk and accelerate time to market.”

The project is expected to deliver what entX describes as a world-first high-power betavoltaic demonstrator, positioning Australia at the forefront of advanced betavoltaic manufacturing. Researchers say the technology could unlock new applications across space, defence and remote systems, while establishing sovereign capability in a strategically significant technology area.

As demand grows globally for maintenance-free, long-duration power solutions, the GenX project highlights how additive manufacturing is being used to translate Australia’s research strengths into commercially competitive technologies.